What are the properties and characteristics of FRP pipes?

(1) Light and high, easy to transport and install (<20% of steel, 10% of concrete)

The specific gravity of FRP pipe is 1.7-1.9. Compared with other material pipes of the same pressure and caliber, the weight of FRP pipe is about 30% of that of steel pipe, so it is very convenient for transportation and installation. The length of each FRP pipe can be up to 12m, which is quick and easy to install. In addition, it can also eliminate the welding, rust prevention and anti-corrosion treatment required for steel pipe installation. The weight of the pipe is only 1/4 of that of ductile iron pipe and 1/10 of that of cement pipe, which is convenient for transportation and unloading and easy to install. The installation technology of FRP pipe is mature, convenient and fast, reducing pipe joints, speeding up the installation and improving the quality of the whole pipe

(2) Corrosion resistance.

Perhaps the main reason for using fiberglass reinforced plastics (FRP) is because of their inherent corrosion resistance. In many cases, they are the only material that can handle a given service environment; in other cases, their corrosion resistance combined with their economics make them the most economically acceptable solution.The corrosion resistance of FRPs is a function of the resin content and the specific resin used in the laminate. In general, the higher the resin content, the more corrosion resistant the laminate.

Chemically inert materials with excellent corrosion resistance and different corrosion resistant pipes are available for transporting media. The conventional thickness of the corrosion-resistant layer is 5 mm. the resin content is greater than 90%, which mainly plays a role in corrosion and leakage prevention. The choice of resin is based on the use of different types of resin. Resistant to acid, alkali, salt, seawater, untreated sewage, corrosive soil or groundwater and many chemical liquids

(3) High mechanical strength and designability

Good resistance to internal pressure, external pressure, and impact resistance, allowing the design and manufacture of pipes and fittings to the required pressure. The anti-corrosion layer can improve the use of FRP pipes under various conditions by adding wear-resistant materials, anti-static materials, flame retardant materials, etc.

The specific properties and shapes of the wound FRP pipes can be designed according to the specific use conditions.

① The winding angle when winding can be designed so that the FRP pipe has different longitudinal/circular strength distribution.

②The wall thickness of the FRP pipe can be designed so that the FRP pipe can withstand different internal and external pressures.

③Materials can be designed to achieve different corrosion resistance, flame retardancy, dielectric properties, etc.

④The front-end way can be designed to adapt to different installation conditions and improve the speed of project installation.

(4) Strong temperature adaptability

Further reading:What is Threading Pipe, and How is it Used to Create Secure Connections in Plumbing and Piping Systems?

What are the advantages of choosing granite headstones for lasting memorialization?

Exploring Types of Guardrail Posts

What is the use of PP fiber in concrete?

Can CDX plywood be used for roofing?

How Long Does It Take to Set Up a Prefab Coffee Shop?

Figure out what are the advantages of spc flooring?

Operating temperature range: greater than -70 degrees Celsius, less than 180 degrees Celsius, can be used normally, the pipeline does not crack in the frozen medium.

(5) Small fluid resistance

The inner surface of FRP pipe is very smooth, the roughness coefficient is small, and the hydraulic coefficient C can be maintained in the range of 145-150 for a long time. Tested, the water friction loss coefficient f is 0.000915, which can significantly reduce the fluid pressure loss along the way and improve transportation. Capacity in more than 20%. Reduce the flow resistance, increase the flow rate and reduce energy consumption. Use smaller diameter pipe to transport the same flow of fluid, than the same size of steel pipe can improve the flow rate of about 10%; it will not scale and reduce the flow rate after long-term use. Excellent protection for cables in disturbed and heavy corrosive environments.

(6) Maintain water quality

The material is non-toxic. FRP pipe is made of resin as the base, glass fiber as the reinforcing material, after a special process to ensure the hygiene and non-toxic, smooth inner wall does not accumulate, does not breed microorganisms, to ensure the quality of the fluid, does not affect the water and other media to produce secondary pollution and transport drinking water, can maintain long-term water quality and hygiene. Water transmission FRP pipe adopts food-grade resin, and the testing indexes all reach international standards.

(7) Widely used, good weather resistance

FRP pipes have good weather resistance and are suitable for harsh environments such as deserts and saline lands.

(8) Material selection

Resin selection: The matrix resin is made of epoxy vinyl resin and phenolic vinyl resin. The fiber is alkali-free fiber or ECR fiber. Meet various anti-corrosion requirements.

(9) Low maintenance cost

The service life of FRP pipe can be more than 50 years, which greatly reduces the maintenance cost. Since FRP pipes have excellent corrosion resistance, abrasion resistance, frost resistance and pollution resistance, there is no need for rust prevention, pollution prevention, insulation, insulation and other measures and maintenance. Buried pipes do not need cathodic protection, which can save more than 70% of maintenance costs.

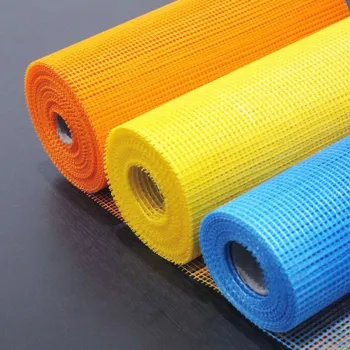

(10) Color

The appearance color of FRP pipes can be made into various colors according to the requirements of customers. The color of appearance can be changed by spraying gel coat resin to adapt to various use environments, with neat and beautiful appearance and vivid colors.

Further reading:

What is a Neoprene Bearing Pad Used For?

What is the downside of a steel frame house?

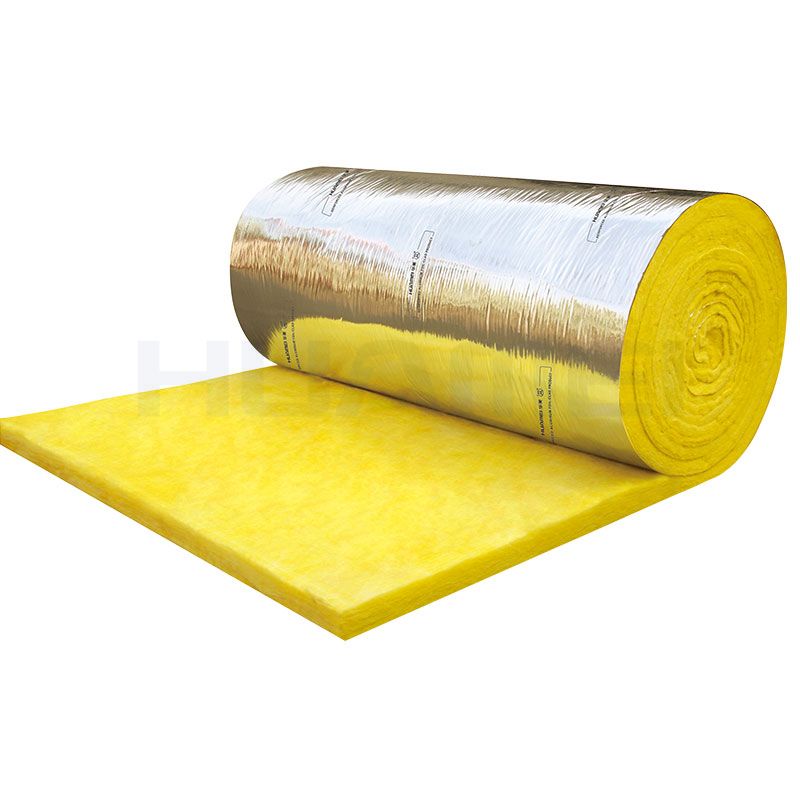

Embracing a Healthier Choice: Formaldehyde-Free Glass Wool Insulation

Demystifying Threaded Rod Grades: What You Need to Know?

10 Tips About Geogrid

From Rustic to Modern: Design Inspirations with Black Stainless Steel

From Snowmobiles to Snow Groomers: The Evolution of Snow Maintenance